Researcher in Residence: Get on your BIO-CYCLE

In industries like automotive, aerospace, sports, marine, and logistics, composites reign supreme, boasting remarkable strength and lightweight properties. However, their conventional counterparts bring along environmental concerns, marked by non-sustainability and significant waste generation. Enter Mahdi Bodaghi (Nottingham Trent University) and the National Composites Centre’s (HVMC) BIO-CYCLE (Bio-Inspired Organic Composites for Yielding Circular Lifecycles through Efficient Manufacturing) project, poised to revolutionise the composite materials landscape with his Researcher in Residence project.

“BIO-CYCLE is the future of sustainable composites, merging advanced 3D printing with eco-friendly materials and latticing strategies to meet industry standards while championing environmental responsibility,” said Mahdi. “At its core, this groundbreaking initiative is focused on crafting Continuous Natural Fiber-Reinforced Bio-Composites (CNFRC). Leveraging natural reinforcements such as flax fibre and bamboo charcoal/chitosan/wheat/mussel micro particles, they will be seamlessly integrated with a bio-based matrix for 3D printing. The result? Ultra-lightweight and resilient lattice composites poised to redefine industry standards.”

The project’s objectives are crystal clear: to elevate the mechanical performance of CNFRCs, positioning them as formidable competitors to traditional composites while meeting stringent industry demands for flame-retardancy, durability, and sustainability. Achieving this feat entails harnessing advanced computer modelling techniques to design optimised lattice structures boasting exceptional strength and energy absorption. Additionally, a comprehensive life cycle assessment will quantify the environmental impact, ensuring sustainability remains at the forefront.

Through robust collaboration with the esteemed National Composite Centre and industrial partners via the Researcher in Residence scheme, this transformative technology will undergo real-world validation across diverse applications. From interior car door modules to impact-absorbing helmet liners and packaging pallet boxes, the potential applications are boundless.

Dr Callum Branfoot, Research Engineer at the National Composites Centre, said: “This project is an excellent example of how materials and manufacturing innovation can help pave the way to a green economy. Advanced manufacturing techniques, lifecycle analysis, and functional materials—BIO-CYCLE is exactly the sort of industry-focused research that the NCC loves to engage with.”

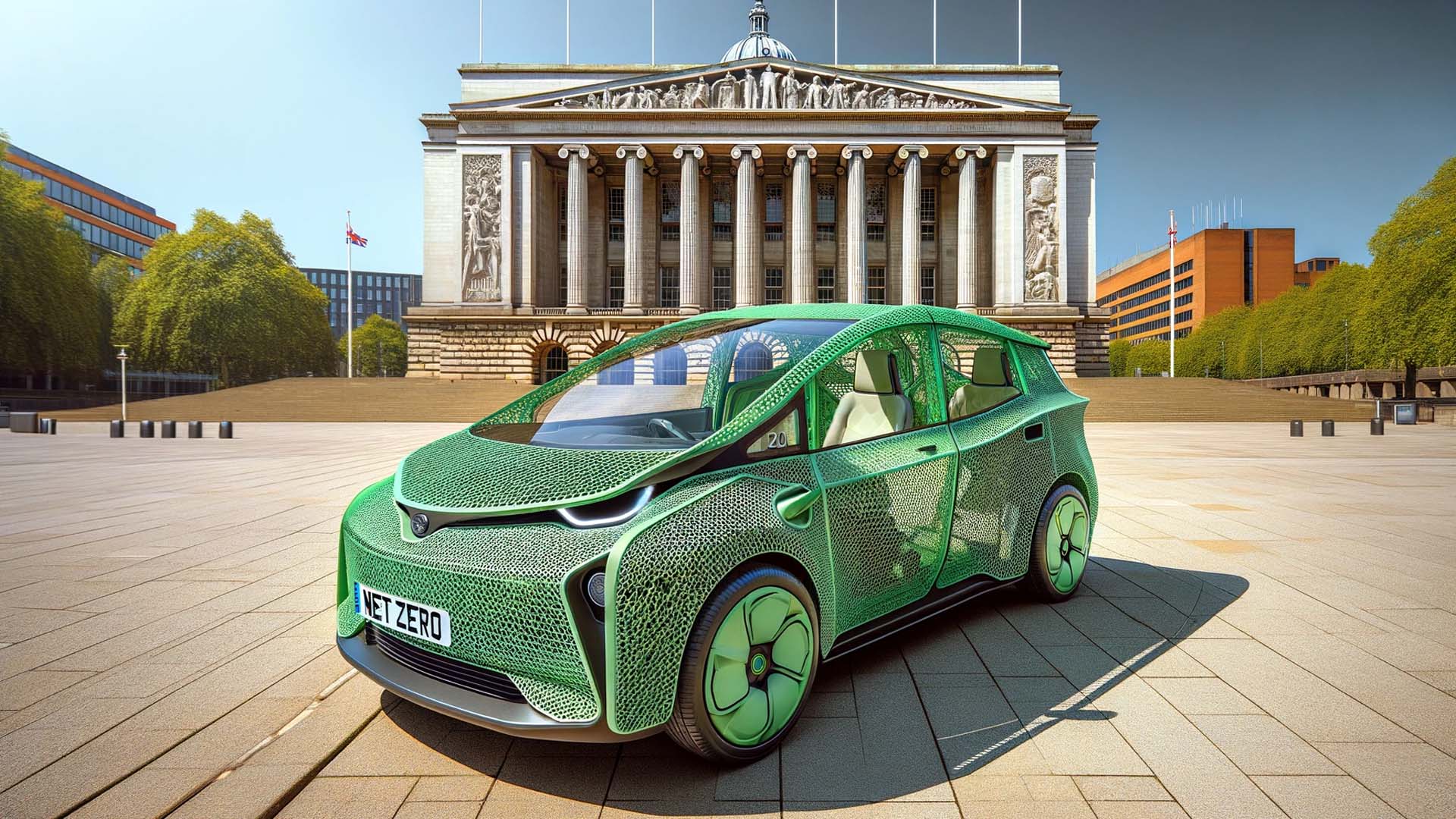

In perfect alignment with the UK’s sustainability goals, the BIO-CYCLE project stands as a beacon of hope, championing resource efficiency, reducing greenhouse gas emissions, and promoting a circular economy. With its sights set on a greener, more sustainable future, BIO-CYCLE paves the way for positive transformation across industries, propelling the UK towards a Net Zero carbon future. Stay tuned as BIO-CYCLE reshapes the landscape of tomorrow’s composites, one innovative step at a time.