Researcher in Residence: Additive Manufacturing – a solution to supply chain disruption?

Led by University of Bristol‘s Philip Davies and in collaboration with Digital Catapult, this project aims to revolutionise spare parts supply chains by leveraging additive manufacturing (AM) technology.

The aim of the proposal is to address the challenges faced by aerospace, defence, and automotive industries in delivering timely and reliable spare parts to customers. By building upon previous research and collaborating with industry partners, Philip aims to elevate the resilience of these supply chains through AM solutions and develop a comprehensive model that integrates AM into supply chain operations, allowing for flexible and efficient responses to disruptions while protecting against future challenges.

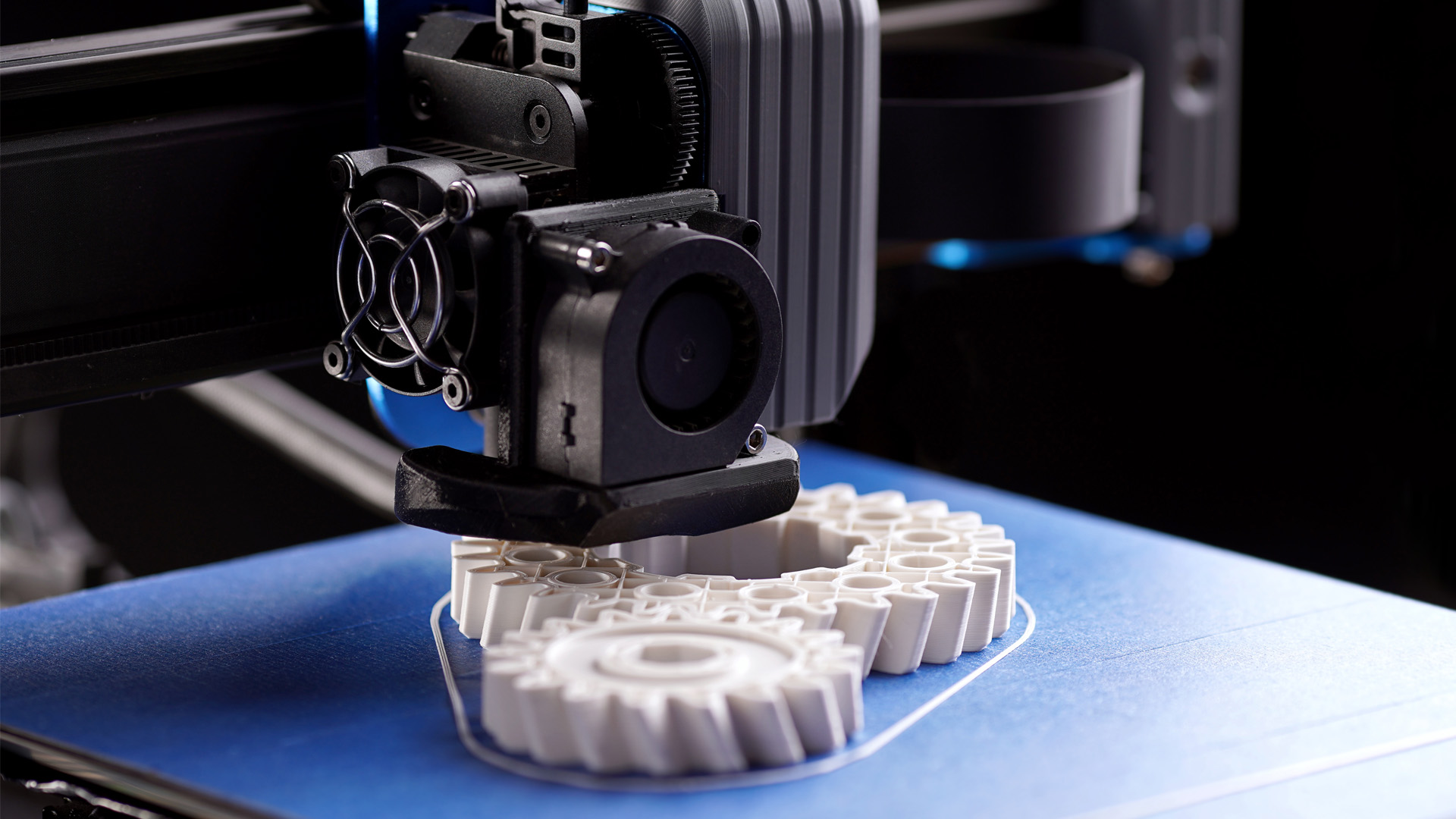

Unfortunately, spare parts supply chains have faced disruptions in recent times, causing delays in delivering parts to customers. Enter additive manufacturing (AM), an emerging technology that holds the promise of offering more flexible, reliable, and faster responses compared to traditional supply chains. With AM, organisations can manufacture parts on demand without the need for costly inventory, as designs can be stored digitally.

Despite its potential, the adoption of AM in spare parts supply chains has been slow, with significant barriers hindering its use. This project aims to address these challenges by building upon previous research and leveraging the Digital Catapult spare parts supply chain testbed whilst also refining the findings from the Responsive Additive Manufacturing to Overcome Natural and Attack-based Disruption (RAMONA) project, working closely with industry partners.

Phil said of the project: “We have seen over the past four years that war, cyber-attacks, natural disasters, and pandemics can significantly disrupt our supply chains or even bring them to a grinding halt. Understanding how to be responsive to disruption through alternative methods of production such as additive manufacturing is crucial for supply chains of the future.”

“The aim of this project, alongside another RiR in engineering, is to develop a responsive and distributed additive manufacturing system that has the potential to unlock another level of flexibility and responsiveness into our supply chains. Whilst we aim to develop a solution to this, my overall aim is to further enhance my long-term collaborations and network with industry, policy makers and the Digital Catapult to position the UK as a leader in secure and responsive additive manufacturing systems and to continue participating in engaged research activities with the relevant bodies.”

This model will empower supply chains to quickly adapt to disruptions using AM and implement technical cyber solutions to safeguard against future disruptions.