Researcher in Residence: Ultra-precision, ultra-promise

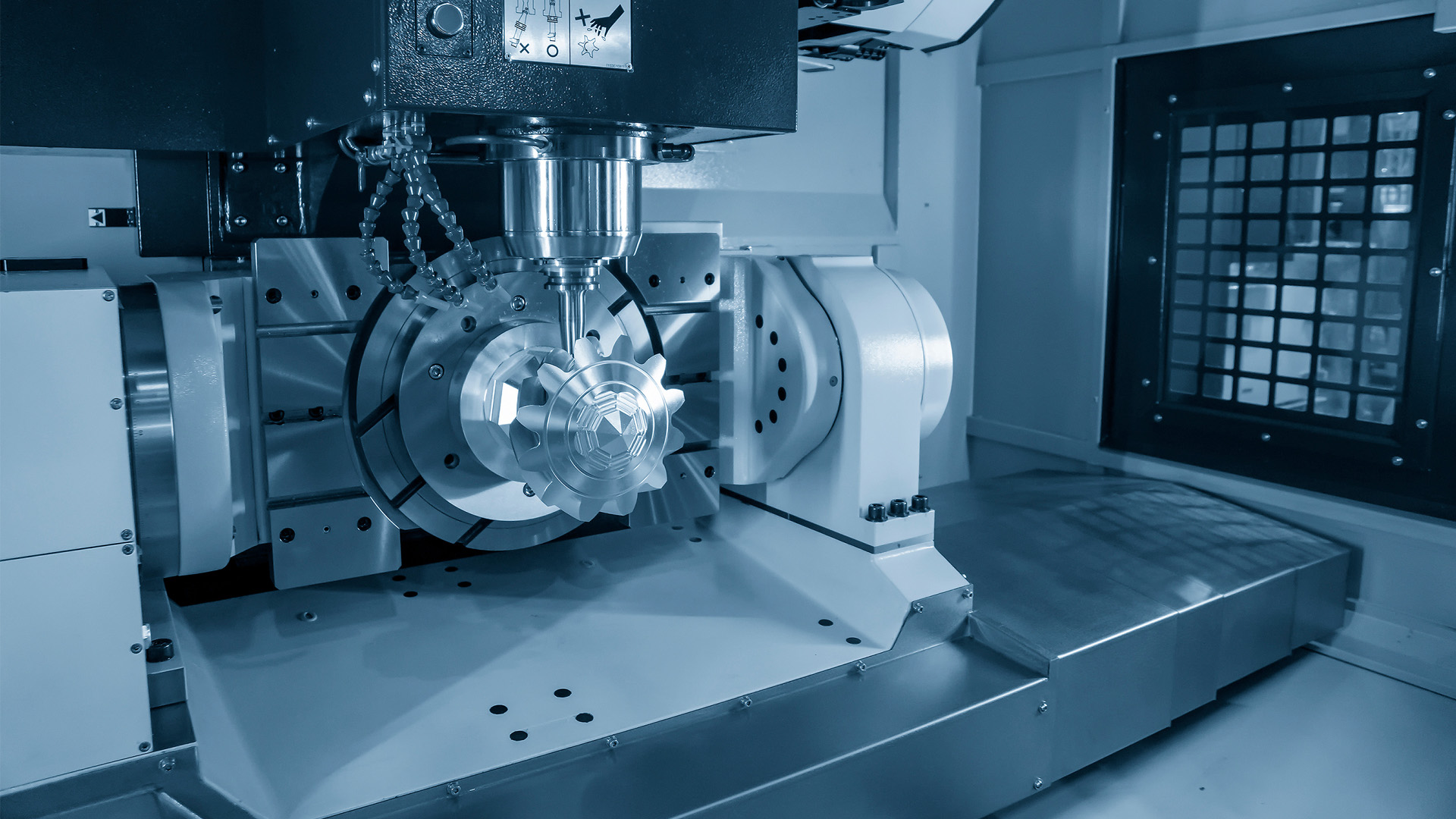

In a world where precision is paramount, the demand for freeform surfaces generated by ultra-precision 5-axis machines is on the rise across various industries. From crafting intricate moulds for AR/VR lenses to engineering knee and hip joint implants for personal health, and even fabricating telescopes for space exploration, these high-value products are crafted from difficult-to-cut materials and require tight tolerances on form accuracy and surface finish. Enter the University of Huddersfield’s Wenbin Zhong, the National Manufacturing Institute Scotland and their collaborative ultra-precision 5-axis machine project.

Enter on-machine surface measurement (OMSM) technology—a game-changer in the realm of precision manufacturing. Unlike conventional offline metrology methods, OMSM eliminates re-clamping errors and maintains the workpiece’s datum for further compensation machining, thereby enhancing metrology efficiency and machining accuracy.

However, integrating OMSM with ultra-precision 5-axis machines poses a significant challenge, mainly due to the complexity of data synchronisation and processing. That’s where this groundbreaking project comes in. Led by Wenbin, the project aims to develop a comprehensive solution encompassing hardware, software algorithms, and calibration strategies to seamlessly integrate OMSM with ultra-precision 5-axis machines.

At the intersection of manufacturing and metrology, this research aligns perfectly with the EPSRC’s manufacturing the future portfolio. The outcomes of this project hold immense promise, not only enhancing the resilience of UK high-value manufacturing but also bolstering associated industry sectors such as optics, medical devices, and space exploration. By reducing the need for outsourcing and import reliance, this project is set to redefine the landscape of precision manufacturing in the UK and beyond.

Wenbin’s said: “In collaboration with NMIS and its world-leading members (such as Renishaw and MSP for metrology solutions, DMG MORI and Matsuura Machinery for machine tools), this research will enhance the resilience of UK manufacturing of high value products with freeform surfaces by improving the accuracy and productivity. Moreover, the enormous data generated from OMSM has the potential of driving digital innovation in manufacturing.”