Researcher in Residence: Bringing confidence to recyclates

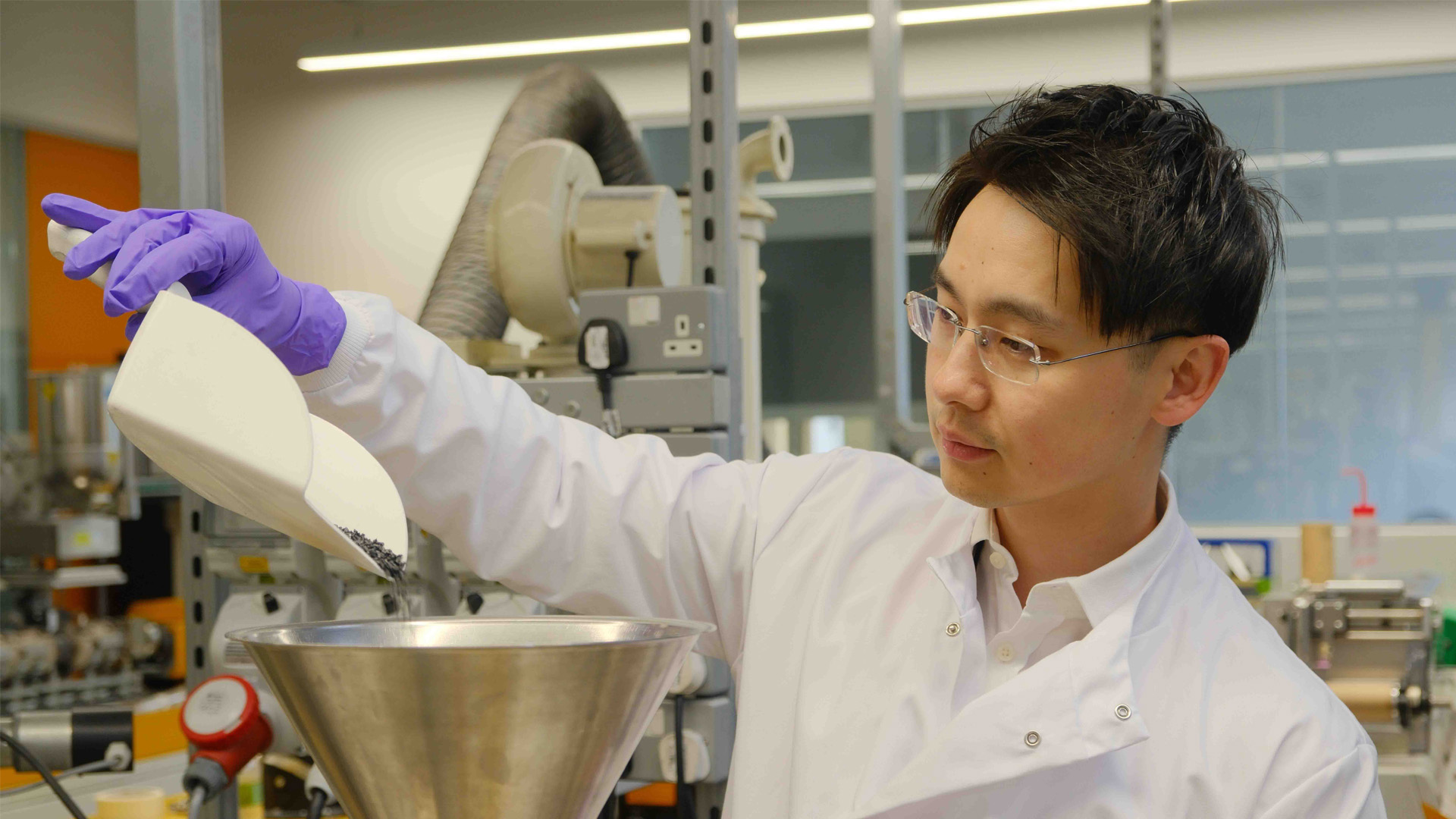

Queen Mary University of London’s Dr Han Zhang’s ‘Recycled Materials Confidence Enhancement via Electrical Sensing’ (RECYCLENS) project aims to address the challenges hindering the widespread adoption of recycled polymers and composites in structural applications, in collaboration with the Warwick Manufacturing Group in a bid to enhance confidence in recyclates.

As the use of recycled materials is key to achieving sustainability goals and promoting the circular economy, the project focuses on developing a novel inspection based on electrical sensing methods. Traditional methods for inspecting recycled materials often struggle with detecting non-visible defects and conducting rapid quality assessments during manufacturing. To overcome these hurdles, the RECYCLENS project leverages electrical sensing methods to provide a cost-effective and swift way to visualise the structural integrity of components made from recycled composite waste.

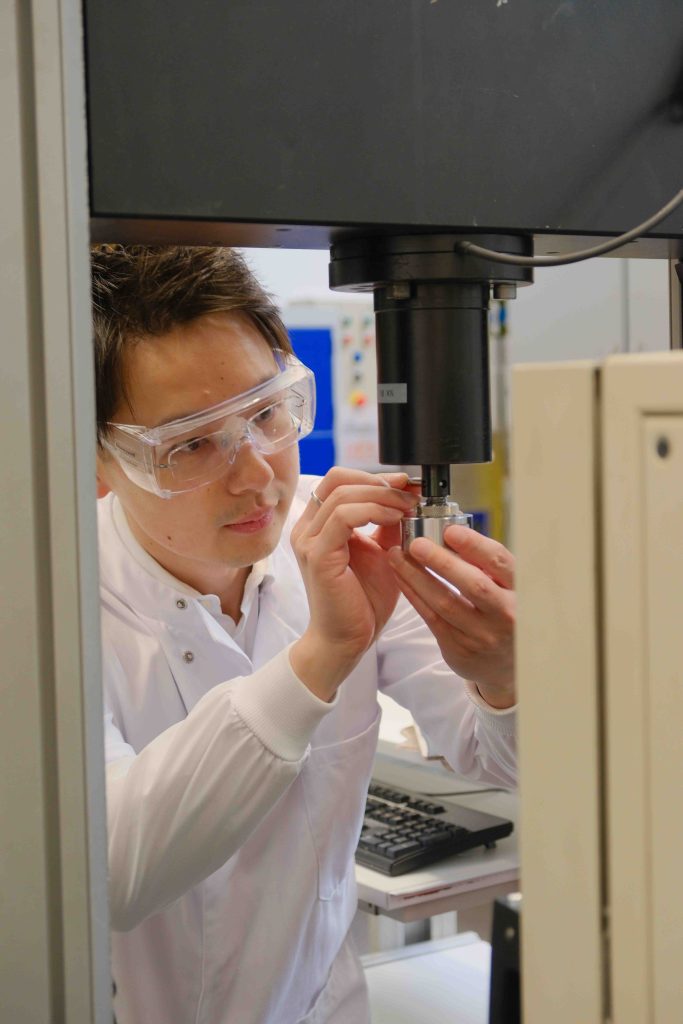

Dr Han Zhang, an expert with over a decade of experience in electrical sensing in polymers and composites, collaborates on this project with the Warwick Manufacturing Group, a key component of the High Value Manufacturing Catapult. In particular, Han has pioneered an integrated in-situ damage sensing method in hierarchical fibre reinforced plastics in the UK, utilising carbon nanofillers to establish neural-like networks for online structural health monitoring of the composite components based on electrical resistance sensing methods. With access to advanced polymer processing and composite manufacturing facilities, Han will explore the application of the electrical sensing in evaluating the quality of recycled carbon fibre (rCF) components.

“I envision our project not only advancing the technical boundaries but also bolstering the confidence of industries in adopting recycled materials for high-stakes applications, thereby driving forward our collective sustainability ambitions.”

By enhancing confidence in the use of recycled materials, the project aligns with the Catapult’s focus on high value manufacturing, sustainability, and achieving Net Zero goals. The research outcomes are expected to contribute to resource efficiency and accelerate the uptake of recyclates in engineering applications.

With the growing demand for sustainable development and circular economy practices, the RECYCLENS project responds to the urgent need to develop reliable composite systems for next-generation lightweight structural applications. As recycled carbon fibres become more commercially available, the project aims to tackle the challenge of confidently utilising and upcycling reclaimed composite waste, paving the way for a more sustainable future.

“Our collaboration with WMG and the High Value Manufacturing Catapult is crucial, as it integrates our strengths to enhance confidence in the structural integrity of recycled materials through advanced sensing technologies,” said Han. “I envision our project not only advancing the technical boundaries but also bolstering the confidence of industries in adopting recycled materials for high-stakes applications, thereby driving forward our collective sustainability ambitions.”