Researcher in Residence: Charging up to Net Zero

A collaborative project between the Innovation Launchpad Network+, University of Liverpool’s Filipe Braga and Centre for Process Innovation (CPI) is set to mark a significant step forward in the development of novel battery chemistries at manufacturing scale in a bid to charge up to Net Zero.

With a focus on bridging the gap between academic research and industrial market needs, this project aims to validate and scale up innovations originating from the University of Liverpool to contribute to the innovation pipeline.

Recognising the strategic importance of batteries in achieving Net Zero commitments, Filipe will target an enhancement of lithium-ion batteries’ lifetime through the addition of advanced protective coatings to cathode materials. This effort aligns with the UK government’s strategy to promote high-skill jobs and positions the UK at the forefront of battery research and development.

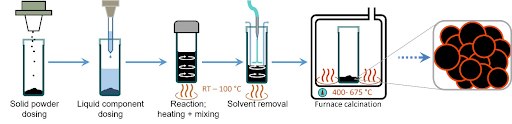

The project’s main activity involves evaluating and validating a 10 mL lab-scale process developed by University of Liverpool and demonstrating its viability at a larger scale of up to 1 litre at CPI. This scale-up evaluation is crucial for testing the coated active materials and facilitating industrial product development. The automated sol-gel coating process will be optimised to ensure its compatibility with production scale and a wider range of battery coating chemistries.

Schematics for coating process developed during RiR project

Ultimately, the project seeks to evaluate the performance of lithium-ion batteries manufactured using these coated cathode materials, paving the way for the development of long-lasting, efficient, and cost-effective energy storage devices. By harnessing the expertise of key stakeholders and leveraging cutting-edge research, this collaboration aims to drive innovation and accelerate the transition to a greener, more sustainable future.

“Improvements in battery technology are required to deliver the UK’s 2050 Net Zero Strategy,” Filipe said. “This project uses the knowledge at the University of Liverpool to develop advanced electrodes with extended cycle life via protective coatings. The coated electrodes have mitigated fading mechanisms while maintaining original properties. By partnering up with the Centre for Process Innovation, we are enabling large scale manufacturing of this material that allows cell testing closer to industrial needs. The partnership with the Catapult also allows training of the researcher so further work can look into reproducing this coating protocol towards novel exciting cell chemistries with reduced cobalt content.”